Having such motors, which designing to operate from a single phase supply, manufacturing for many applications in home, offices, factories, workshop etc. Since the performance requirement of the various application. Single-phase may be classified many kind of type, depending on their structure and method of starting:

- Induction motors (split-phase, capacitor and shaded-pole etc)

- Repulsion motors (also called inductive-series motors)

- AC series motors

- Un-excited synchronous motors

Now, we will finger out popular using most in industry and home application-Induction motors.

I. Single phase induction motor

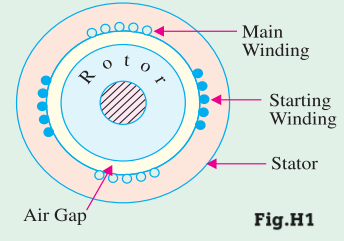

About structure, more or less, this motor rather similar to a polyphase induction motor, except that it’s stator is provided with a single-phase winding and a centrifugal switch is used in some types of motors for cutting out a winding, used only for starting purposes. It has a stator winding and a squirrel-cage rotor. When it be supplied from single-phase supply, stator winding produces a field which is alternating along one space axis only. It is not a synchronously rotating field, as in the case of a two or a three-phase stator winding, fed from a 2 or 3 phase supply. As you known, an alternating field acting on a stationary suirrel-cage rotor canot produce rotation (only a rotating field can). That is why a single-phase motor is not self-starting.

However, if the rotor of such a machine is given an initial start by hand or otherwise, in either direction, then immediately a torque arises and the motor accelerates to its final speed (unless the applied torque is too high)

This peculiar behaviour of the motor will be explain in two ways: by two-field or double field rotating theory and by cross-field theory. We will disscuss briefly the first theory together.

II. Making Single-Phase induction motor Self-starting

As discussed above, a single-phase induction motor is not self-starting. To overcome this drawback and make the motor self-starting, it is temporarily converted into a two-phase motor during starting period. For this purpose, the stator of a single-phase motor provide with an winding more, known as starting (or auxiliary) winding, in addition to the main (or running) winding. The two winding set distance to each othes 90° electrically apart and connecting in parallel across the single-phase supply as shown below figure.

It is so arranged that the phase-difference between the current in the two stator windings is very large (ideal value being 90°). Hence, the motor behaves like a two-phase motor. These two currents produce a rotating field and hence make the motor self-starting.

It is so arranged that the phase-difference between the current in the two stator windings is very large (ideal value being 90°). Hence, the motor behaves like a two-phase motor. These two currents produce a rotating field and hence make the motor self-starting.

There are many methods that make phase-difference between the two currents.

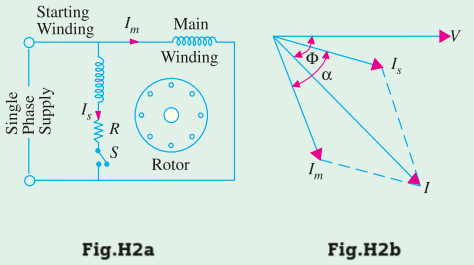

In split-phase motor, shown in Fig.H2a, the main winding has low resistance but high reactance whereas the starting winding has a high resistance, but low reactance. The resistance of the starting winding may increase either by connecting a high resistance R in series with it or by choosing a high-resistance thin copper wire (R=δL/S) for this purpose.

Hence, as shown Fig.H2b, the currents ${I_s}$ drawn by the starting winding lags behind the apply voltage V by a small angle wheareas current ${I_m}$ taken by the main winding lags behind V by a very large angle. Phase angle between ${I_s}$ and ${I_m}$ is made as large as possible because the starting torque of a split-phase motor is proportional to sinα. A centrifugul switch S (or relay) will connect in series with the starting winding and is located inside the motor. It’s function is to automatically disconnect the starting winding from the supply when the motor is reach 70 to 80% of its full-load speed.

Hence, as shown Fig.H2b, the currents ${I_s}$ drawn by the starting winding lags behind the apply voltage V by a small angle wheareas current ${I_m}$ taken by the main winding lags behind V by a very large angle. Phase angle between ${I_s}$ and ${I_m}$ is made as large as possible because the starting torque of a split-phase motor is proportional to sinα. A centrifugul switch S (or relay) will connect in series with the starting winding and is located inside the motor. It’s function is to automatically disconnect the starting winding from the supply when the motor is reach 70 to 80% of its full-load speed.

III. Application range

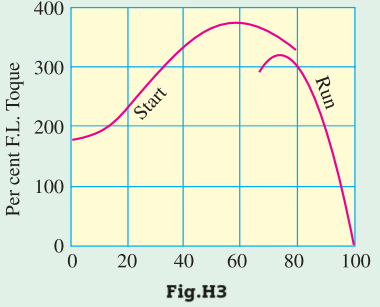

A typical torque/speed characteristic of such a motor is shown in Fig.H3. As seen, the starting torque is 150 to 200% of the full-load torque with a starting current of 6 to 8 times the full-load current. These motors are often use in preference to the costlier capacitor-start motors. Typical applications are fans and blowers, centrifugal pumps etc. Commonly available sizes range from 40 to 250W with speeds ranging from 3450 to 865rpm.

III. Reversing direction

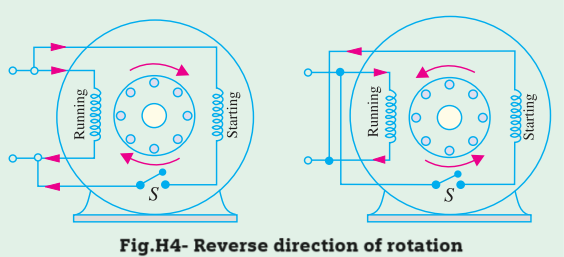

As shown in Fig.H4, the direction of rotation of such motor can be reversed by reversing the connection on of two stator winding (not both). For this purpose, the four leads are brought outside the frame for customing direction of rotation fit to specular applications.

The speed regulation of standard split-phase motors is nearly the same as of the 3 phase motors. Their speed varies about 2 to 5% between no load and full-load. For this reason such motors are usually reagard as practically constant-speed motors.

The speed regulation of standard split-phase motors is nearly the same as of the 3 phase motors. Their speed varies about 2 to 5% between no load and full-load. For this reason such motors are usually reagard as practically constant-speed motors.

Hope to this lession is useful for you, If having any question and topic need to make clearly. Leave comment bellow for me. Thanks and love!